What Are Ear Plugs Made Of?

time2023/07/28

- Earplugs are usually made of a soft, stretchy material that fits easily into the ear canal to reduce the volume of sound reaching the eardrum. Read on to learn more about the earplug-making process.

Ear plugs are a common hearing protection device used to prevent hearing damage from exposure to loud noises. They are usually made of a soft, stretchy material that fits easily into the ear canal to reduce the volume of sound reaching the eardrum. In this article, we'll take a closer look at what ear plugs are made of, the steps involved in making them, and the quality checks for ear plugs.

What Are the Common Types of Ear Plugs?

Foam Ear Plugs

One of the most common types of earplugs is foam earplugs, which are made of a soft, compressible foam material. Once inserted into the ear canal, the foam expands to create a seal that blocks out noise. These ear plugs are usually made of polyurethane foam, which is known for its softness, comfort, and durability. Generally used for sleep and travel, such as foam sleep earplugs and foam travel earplugs.

Silicone Ear Plugs

Silicone earplugs are another popular type of ear plugs, made from a soft, stretchy silicone material. Silicone is known for its high level of comfort. Silicone is a material that does not cause allergies and is widely used in medical and daily life. The silicone material is also waterproof. This makes silicone earplugs ideal for use in environments where prolonged wear is required. Swimming, musician, and industrial earplugs are often made of silicone.

Waxed Cotton Ear Plugs

Waxed cotton ear plugs are a traditional type of ear plug that has been used for centuries for noise protection and waterproofing. They're made from a soft, moldable wax material that can be easily shaped to fit the contours of your ear canal. While wax earplugs are not as common as foam or silicone earplugs, due to the wax cotton earplugs being composed of natural wax and medical cotton, they are still used by some people due to their natural feel and ability to conform to the shape of the ear canal.

TPE Ear Plugs

Made of thermoplastic elastomer, TPE earplugs are a cutting-edge innovation in hearing protection. These soft, flexible, and hypoallergenic ear plugs provide a comfortable, secure fit for users of all ages. TPE ear plugs have excellent noise-canceling properties, are perfect for a variety of environments, and are often used as musician earplugs. Their durability and reusability make them a cost-effective and environmentally friendly choice for effective noise reduction and hearing health.TPE earplugs are usually softer and cheaper than silicone earplugs of the same type. But after burning, black smoke will be generated.

Custom Ear Plugs

Custom earplugs are personalized hearing protectors that are tailored to an individual's unique ear canal shape. Made from high-quality materials, they provide excellent comfort, effective noise reduction, and a secure fit. Whether for musicians, industrial workers, or everyday use, custom ear plugs provide unrivaled sound isolation to ensure optimal hearing health. Customized earplugs require reverse molding of the customer's ear canal, which is a unique earplug that fits the ear canal. It can ensure maximum noise reduction effect, but the corresponding cost is relatively expensive..

Why Custom Ear Plugs Are the Best Choice?

Cost is an important factor when considering earplugs. While regular earplugs may seem cheap on their own, their cumulative cost can add up over time. In the long run, custom earplugs become the more financially sensible choice. Additionally, the custom earplugs are designed for a perfect fit and provide superior comfort, ensuring a comfortable, secure experience. Unlike regular foam ear plugs, custom ear plugs can be used anywhere, even in the pool. They also last longer due to the durable material. Best of all, the custom ear plugs provide superior sound protection by precisely fitting the contours of the ear canal to effectively dissipate sound wave energy.

How Are Ear Plugs Made?

The manufacturing process of ear plugs is a fusion of art and science, incorporating advanced technology to produce a high-quality product. Here's a step-by-step overview of the process:

Step 1: Material Selection

The first critical step is choosing the right ear plug material. Material selection is based on factors such as comfort, noise reduction and durability. Common materials include foam, silicone, and special blends.

Step 2: Create the Mold

Next, prepare the mold according to the desired ear plug design. These molds are the basis for shaping the ear plugs during the manufacturing process. The mold is not disposable and can be used multiple times. However, as the number of uses increases, the mold will also experience wear and tear. Replacement is required.

Step 3: Material Preparation

The selected material is carefully prepared to ensure it reaches the ideal consistency required for molding.EASTRAGON has top raw material suppliers who conduct screening and testing of raw materials during procurement.

Step 4: Injection Molding

The prepared material is then injected into the mold. This process ensures uniformity and consistency in the shape and size of the ear plugs.

Step 5: Cool and Solidify

After injection, the ear plugs begin to cool and solidify within the mold, forming their final shape.

Step 6: Trim and Organize

Once the ear plugs have been set, they are carefully removed from the mold and given trimming and finishing touches. This step ensures that the earplugs have a smooth, comfortable surface.

Quality Control in Earplug Manufacturing

Quality control is critical to ear plug manufacturing. The manufacturer conducts rigorous testing to ensure that each pair of earplugs meets strict safety and performance standards. Thorough inspections ensure that the final product is effective and reliable in reducing noise.

Quality Control Steps in the Manufacture of Eastragon Ear Plugs

Raw Material Inspection: The first step is to thoroughly inspect the raw materials used to manufacture the ear plugs. This includes checking for material defects, consistency, and compliance with safety regulations.

Mold Inspection: For custom molded ear plugs, molds play a vital role in achieving a perfect fit. Quality control includes checking molds for accuracy and precision.

In-Process Inspection: Throughout the manufacturing process, Eastragon conducts regular inspections to verify that each step is performed correctly. This includes monitoring the injection molding process, cooling and solidification of the ear plugs, and other critical stages.

Noise Reduction Test: One of the most critical quality control checks is the Noise Reduction Rating (NRR) test. This test determines how well ear plugs reduce noise. Eastragon conducts NRR testing using standardized procedures to provide accurate ratings.

Fit and Comfort Tested: To ensure user comfort, the earplugs are fit and comfort tested. This involves testing the fit of the ear plugs in various ear canal shapes and sizes to ensure they provide a secure and comfortable seal.

Hygiene and Cleanliness: Hygiene is paramount when it comes to reusable ear plugs. Quality control ensures that proper cleaning procedures are followed and that the ear plugs are free of any contaminants or foreign particles.

Eastragon--Your Custom Hearing Protection Ear Plug Expert

Eastragon is a professional custom hearing protection earplugs earmuffs manufacturer that can create exclusive ear plugs to meet your specific needs. Whether you need ear plugs for concerts, sleeping, swimming, traveling, special work, or filming, we can provide you with the best-customized solutions. Our ear plugs are made of a variety of materials, including silicone, polyurethane foam, silicone sponge, wax ear plugs, and rubber ear plugs to meet different needs. Our ear plugs feature highly effective noise reduction, superior comfort, and a great fit for different ear shapes. We can provide individual design and customization to ensure that your ear plugs exactly meet your requirements and expectations. Eastragon offers customization options such as color, labeling, and packaging to ensure your earplugs match your brand image perfectly.

Eastragon's production process uses advanced digital technology to ensure the best quality and precision for your earplugs. Our team will work closely with you to ensure your custom ear plugs are a perfect fit with your brand image. If you need a personalized solution for custom ear plugs, please do not hesitate to contact us. Our professional team will provide you with the best custom ear plug service.

Noise Cancelling Bell-shaped-Noise Reduction Foam Earplug ES3002 For Peace and Quiet Perfect For TravelStudy, Sleep

The filter earplug ES3116 has three layers of blades to filter noise and provide high fidelity

Three-layer filter earplugs ES3126 for effective noise reduction. Has good waterproof properties

TPE Earplug ES3109 Can Achieve Good Noise Reduction Effects When You taking a nap on the plane

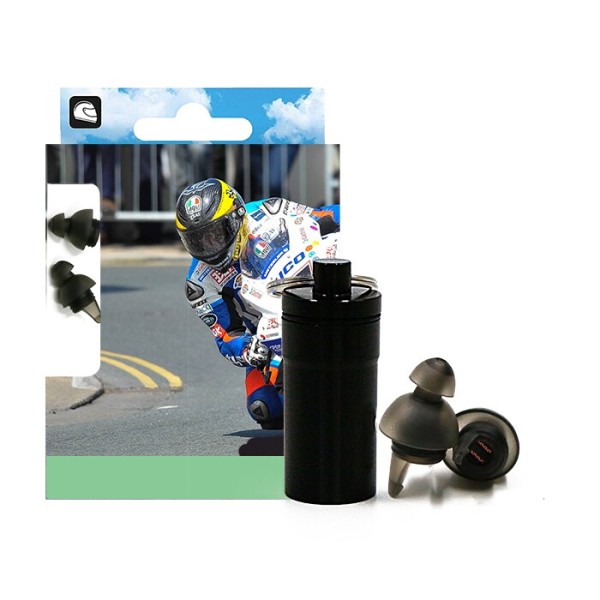

Professional cycling wearing filter earplugs ES3132, TPE material is soft and reusable